MKLS-FS-CA-SYST26 Minkels Nexpand Buidling the full solution - Free Standing Cold Aisle System

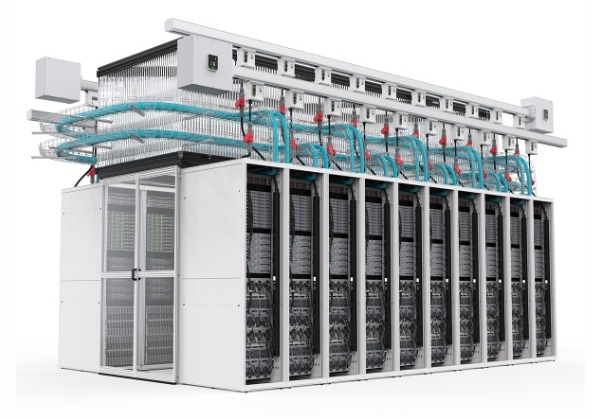

Minkels Nexpand Aisle containment with full Wiring and power BusBar Standing Cold Aisle System

![]()

Description:

Minkels Free Standing Cold Corridor Minkels has expanded its product portfolio with the Free Standing Cold Corridor®, an ultra-modular and cost efficient, free standing aisle containment system. This free standing system offers pay-as- out-grow options for separating warm and cold air flows in an energy efficient manner, enabling investments in racks to be spread out over time. All modular product options for the Next Generation Cold Corridor® introduced last year can be integrated. The Minkels Free Standing Cold Corridor® is a fully free standing aisle containment system that – contrary to common use in the data centre market – can be used to create closed corridors independently from the IT racks. The Free Standing Cold Corridor provides the same energy efficiency immediately upon implementation as a standard Cold Corridor system with IT racks. The system, a modular design comprised only of a support structure, wall panels, roofing and doors, offers corporate and commercial data centres a cost-efficient “pay-as-you-grow” solution so that they can create energy efficiency with very little initial investment costs (CAPEX). The Free Standing Cold Corridor also provides far reaching flexibility when it comes to installing racks and equipment like storage and network systems. Different types and sizes of racks can be adapted to the design, so that users have the freedom to customise the Cold Corridor system to their varying and dynamic data centre needs over time. Note that the purpose of the racks is not to support the Free Standing Cold Corridor system.

Features:

ADD-ON MODULES AND RETROFIT APPLICATION The Minkels Free Standing Cold Corridor® system is compatible with the Minkels Next Generation Cold Corridor®. The main benefit is that all modules of the Next Generation Cold Corridor can be seamlessly integrated with the Free Standing Cold Corridor.

Choices include:

- Highly translucent or pivot roofing system

- Sliding panel doors - can be operated mechanically or electronically

- Air flow optimisation - to increase energy efficiency

- Data centre monitoring - with plug & play integration of monitoring sensors

- Access security - both mechanically and electronically

- Fireproofing - for compatibility with a variety of fire extinguishing systems

The Free Standing Cold Corridor is also ideal for so-called retrofit situations, such as an existing data centre environment that requires an energy efficient aisle containment system without any risk to the operational continuity of the data centre.

Minkels Free Standing Cold Aisle Frame

![]()

Specification:

Minkels Free Standing Corridor

GENERAL:

Aisle width (A) mm 1200 / 1350 / 1800 ¹

Net aisle width (N) mm 1370 / 1520 / 1970 ²

Free height available for use (H) mm 2220 / 2420

Overall height (T) mm 2385 / 2585

Module length (M) mm 1800 to 9600 in steps of 600

Colours RAL 7047 / RAL 9011

Materials Sheet steel, powder coating

Operating conditions Max. 5 to 40°C / 20 to 80% RH

Air flow optimisation Yes Standards Not applicable

PORTAL:

Portal type Single ³, double

Portal depth mm 100

Access control - build-in points Left and right

Inside and outside

Access control - outside Only applicable if an electrical sliding door system is selected

Push button Standard

Motion sensor Optional

Keypad Optional - wireless (Wi-Fi). Powered by 4x LR6 AA alkaline batteries. Expected battery life: 3.5 years

RFID card reader VariControl-L

Access control - inside Push button. Only applicable if an electrical sliding door system is selected

Assembly Fully self-supporting. The portal should be attached to the floor using screws

Sliding door system Fully compatible with the Minkels Next Generation Cold Corridor sliding door portfolio ⁴

LENGTH WISE BEAMS:

Segment lengths mm 1000, 1200, 1600, 2400 (400mm length wise beam is included per portal)

Maximum length that can be bridged without support (S) mm 3700. Distance between vertical supports

Roof system Fully compatible with the Minkels Next Generation Cold Corridor portfolio ⁵

VERTICAL SUPPORT OF LENGTHWISE BEAMS:

Dimensions mm Height (H) x 50 x50

Adjustment Continuously adjustable

Adjustment range mm 3300 +/- 350 with respect to the assembly position ⁶

Attachment to the length wise beam Using a knob

VERTICAL WALL SYSTEMS:

Full height Width mm 50, 100 to 150, 150 to 400, 350 to 625, 625+ ⁷

Height mm 2200 / 2400

Filler panels

Width mm 500 -1000

Height mm 100 – 600 ⁸

19” cut-away Optional – 3U

Partition wall

Width mm 1200 / 1350 / 1800

Height mm 2200 / 2400

Placement and assembly

Attached to the floor Fitting strips should be screwed or glued to the underlying floor

Wall connection Using quick-fit connectors (cross-head)

Partition wall Quick-fit connector to the vertical supports of the lengthwise beams or using a quick-fit connection to the adjacent wall

1 Optimum aisle widths between the racks. Non-standard aisle widths can be achieved by placing the racks used at a different position under the length wise beams

2 Aisle width between the wall panels (if applicable)

3 The portal has an extra connecting post and filler panel if a single sliding door is used

4 The entire range of sliding doors from the Minkels Next Generation Cold Corridor can be used with the Free Standing Cold Corridor portal. If an electric sliding door is used, there is then of course no need to put in the standard Next Generation portal. This function is taken over by the Free Standing Cold Corridor portal.

5 The complete roofing portfolio of the Minkels Next Generation Cold Corridor can be applied in the Minkels Free Standing Cold Corridor concept. The function of the roof rails is however integrated into the length wise beams.

6 The position of the vertical supports should be determined using the information given in the user manual and/or installation manual. The vertical supports may only be moved if the maximum width that can be bridged unsupported (3.7m) is not exceeded.

7 If other dimensions are required, please contact the Minkels sales department.

8 The filler panels can be made/ordered in whatever size is required. Please note: assembly strips should be taped to the underlying construction (e.g. the rack).